|

|

At Sine, we have extensive experience in handling batteries for electric motorcycles. Over the years, we have provided more than 100 different options of battery packs, including NiCad, NiMH, LiFePO4, LiPo, and Lithium-Ion, with various voltages, shapes, and sizes.

Battery Options

Sine's battery lineup for 2023 consists of a diverse range of lithium batteries. Each package is equipped with Anderson Powerpole connectors on the discharge cable and incorporates a sturdy BMS circuit to safeguard against issues like overcharging, excessive discharging, and excessive current flow.

36V10Ah  | Our tiniest battery option is designed for individuals who need to transport or take their electric bike on flights. Each unit has a capacity of 36V 10Ah, which amounts to approximately 400 watt-hours, making it exempt from many weighty shipping limitations. You can combine these modules in parallel to increase the capacity as needed, or connect them in series to create 72V arrangements. |

60V20Ah | We have high-quality batteries that use ternary lithium batteries. Featuring a large capacity of 60V20Ah and supporting fast charging Maximum continuous current 17A, battery weight 7.2kg, battery size 230 * 180 * 174, suitable for 800w motor |

e60V40Ah HT type black iron shell | 60 Å 40AHT type black iron shell battery cell ternary normal working current (A ≥ 20 standard voltage (V) 60 maximum continuous current (A25 standard capacity (Ah) battery weight (kg) 0 ℃ capacity retention rate battery size (mm) 359 * 219180 * 150 charging constant current value (A) 3-5 temperature characteristics charging 0 ° C-45C charging time (hr) temperature characteristics discharge -20 ° C-45 ° C discharge termination voltage (V) ≥ 51 temperature characteristics storage 20 ° -45 ° C applicable motor (W) 1200 |

72V40Ah Black iron shell | Normal working current (A) standard voltage (V) maximum continuous current (A ≥ 25 standard capacity (Ah) battery weight (kg) 200 ℃ capacity retention rate 95% battery size (mm) 220 * 180 ° 346 charging constant current value (A) temperature characteristic charging 0 ° C~45 ° C charging time (hr9-20 temperature characteristic discharge 20 ° -45 ° C discharge termination voltage (V temperature characteristic storage 20 ° -45 ° C applicable motor (W) 1200 |

How to Choose a Pack

The first thing to consider when selecting a battery pack is ensuring that it can handle the power needed by your motor controller. If your motor controller requires 40A, but your battery can only deliver a maximum of 25A, then either the battery management system will shut off the battery when you go full throttle, or the battery will be strained and its lifespan will be reduced. On the other hand, if your battery has a higher current rating than what your controller needs, there is no problem at all. In fact, it can be quite advantageous.

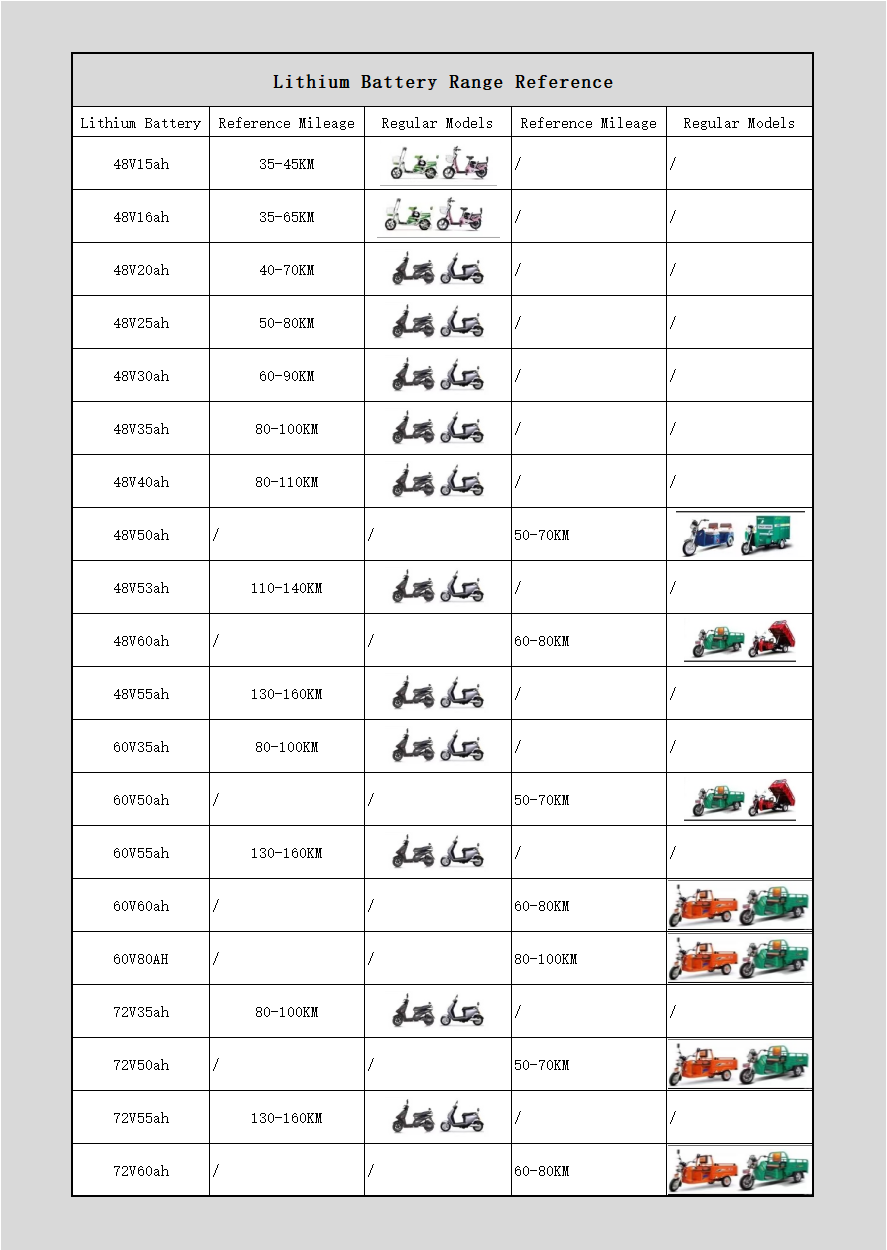

The next thing to consider is making sure that the battery is big enough to cover the distance you need to travel. It's not enjoyable to have a battery go dead before reaching your destination. To determine the range you can expect from a specific battery, you need to know both the watt/hour capacity of the battery and how much energy you consume per kilometer. It may sound complicated, but it's actually quite simple. As a general guideline, most people riding an electric motorcycle at average speeds consume around 15 watt/hours per kilometer from their battery, making the calculations easy. For example, if you have a 400 watt-hour battery, you can expect a range of approximately 27 kilometers. With a 720 watt-hour battery, you can expect a range of approximately 48 kilometers.

Naturally, if you drive at high speeds or carry a heavy load, the mileage will decrease significantly, reaching around 20-25 wh/km. Conversely, if you utilize the motor more conservatively, you can effortlessly decrease it to 10-15 wh/km. The chart provided outlines the projected distance that various battery examples can cover based on light, moderate, and intense usage scenarios.

The size of the motor on your Electric motorcycle, be it a small hub motor, a large direct drive motor, or a mid-drive motor, doesn't really matter much. The distance you can cover and the range you can achieve with a specific battery depend on how you utilize the Electric motorcycle, rather than the type of motor system it has.

Hint: You will never feel remorseful for having excessive battery capacity.

The Case for Extra Capacity

Imagine you have a daily commute of 20 kilometers to work and back. To complete the entire 40-kilometer round trip, you would require 600 watt-hours of energy. In this case, wouldn't a 48V 20Ah battery with 600 watt-hours be the perfect choice?

Well, the truth is, unless you have strict budget or weight limitations, investing in this battery might not be the best decision. While it may initially meet your commuting needs, it leaves no room for unexpected situations like running errands on the way home or forgetting to charge it overnight. Moreover, discharging the battery to a lower level, such as 80 or 90%, can significantly reduce its cycle life and calendar life.

Additionally, a larger battery offers the advantage of lower stress per cell during discharge. This is because the current is distributed among more parallel cells. Batteries that are discharged at high currents (>1-2C) tend to have a noticeably shorter cycle life compared to those discharged at lower currents.

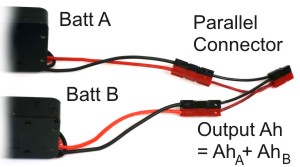

Parallel Connecting Batteries

One of the simplest ways to enhance the current handling ability and range is by combining two or more batteries in parallel. Generally, this poses no issue with lithium batteries of the same voltage. It is acceptable to mix older and newer lithium batteries in parallel, or even batteries from different manufacturers and capacities, as long as they share the same voltage. We offer a parallel battery connection cable to make connecting packs in this manner easier.

However, charging parallel connected batteries can be a bit tricky. If you charge the batteries while they are still in parallel, the charging current will be divided among them, ensuring they maintain the same charge level. However, this does have its drawbacks in terms of pack performance.

Alternatively, you can separate the batteries and charge each one individually using its own charger, and then connect them in parallel only for discharging. Just ensure that both packs are fully charged before connecting them together, as it is not advisable to connect a fully charged pack with a depleted one.

48V or 60V or 72V?

We have an equal demand for our battery packs in 48V, 60V, and 72V. Our conversion kits and controllers are compatible with all three options without any issues. It is important to note that a higher voltage, such as 72V, does not necessarily mean that an Electric motorcycles is superior, more powerful, or faster compared to a 48V Electric motorcycles. Despite what you may find on the internet, most of the time you can switch between these options without causing any harm to the existing electronics.

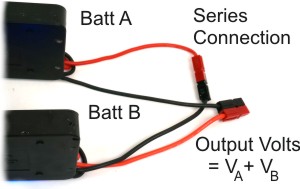

Series Connecting for 72V?

It is theoretically possible to connect two 36V batteries together to create a 72V setup. However, the only battery specifically designed for this is our LiGo modules. For all other batteries, it is important to use a pass diode across the output of each battery. This prevents a large negative voltage from being exposed when one BMS circuit trips. We offer a special series battery cable with this diode already integrated.

When connecting batteries in series, it is crucial to ensure that they have the same capacities and specifications. Additionally, you need to set either your controller or Cycle Analyst low voltage cutoff so that the discharge stops when one pack trips. If this is not done, continuous current will flow through the pass diode when you are using only the non-tripped battery. This can cause the diode to overheat and malfunction.

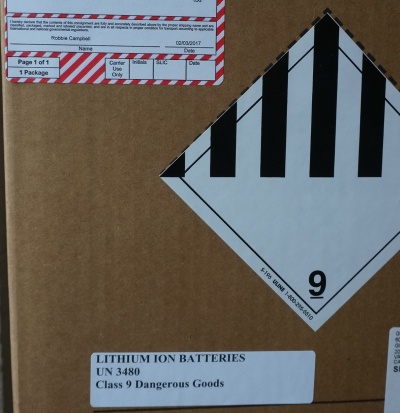

Battery Shipping

The transportation of lithium batteries is a complex task that poses challenges for the logistics of supplying and supporting Electric motorcycle conversion kits. Due to several incidents where lithium batteries emitted smoke or caught fire during transit, the entire transportation industry recognized the need for strict regulations governing their shipment. These regulations are continually evolving, but generally, ebike batteries are classified as Class 9 Dangerous Goods. To transport a lithium battery, whether by ground or air, one must adhere to strict packaging and labeling requirements. The battery must also possess UN38.3 test certification, and the individual responsible for packing and shipping must be trained and certified in proper handling procedures.